Solvent Filter: Your Ultimate Guide To Purification And Beyond

Ever wondered what a solvent filter is and why it’s so important in labs and industries? Well, buckle up because we’re diving deep into the world of solvent filtration. Whether you’re a scientist, engineer, or just someone curious about the science behind clean solvents, this article has got you covered. From its uses to its types, we’re breaking it all down for you.

Now, let’s be real here. Solvent filters might sound like a boring topic at first glance, but trust me, they play a crucial role in everything from pharmaceuticals to chemical processing. If you’ve ever sipped on a perfectly purified liquid or used a product that required spotless solvents, chances are, a solvent filter was involved somewhere along the line.

So, why are we talking about this? Because understanding solvent filters can help you appreciate the science behind keeping things clean, precise, and efficient. Stick around, and we’ll unravel everything you need to know about these unsung heroes of purification.

- Travis Mills Girlfriend 2025 The Untold Story You Need To Know

- Tyga And Amanda Trivizas A Modernday Love Story You Need To Know

What Exactly is a Solvent Filter?

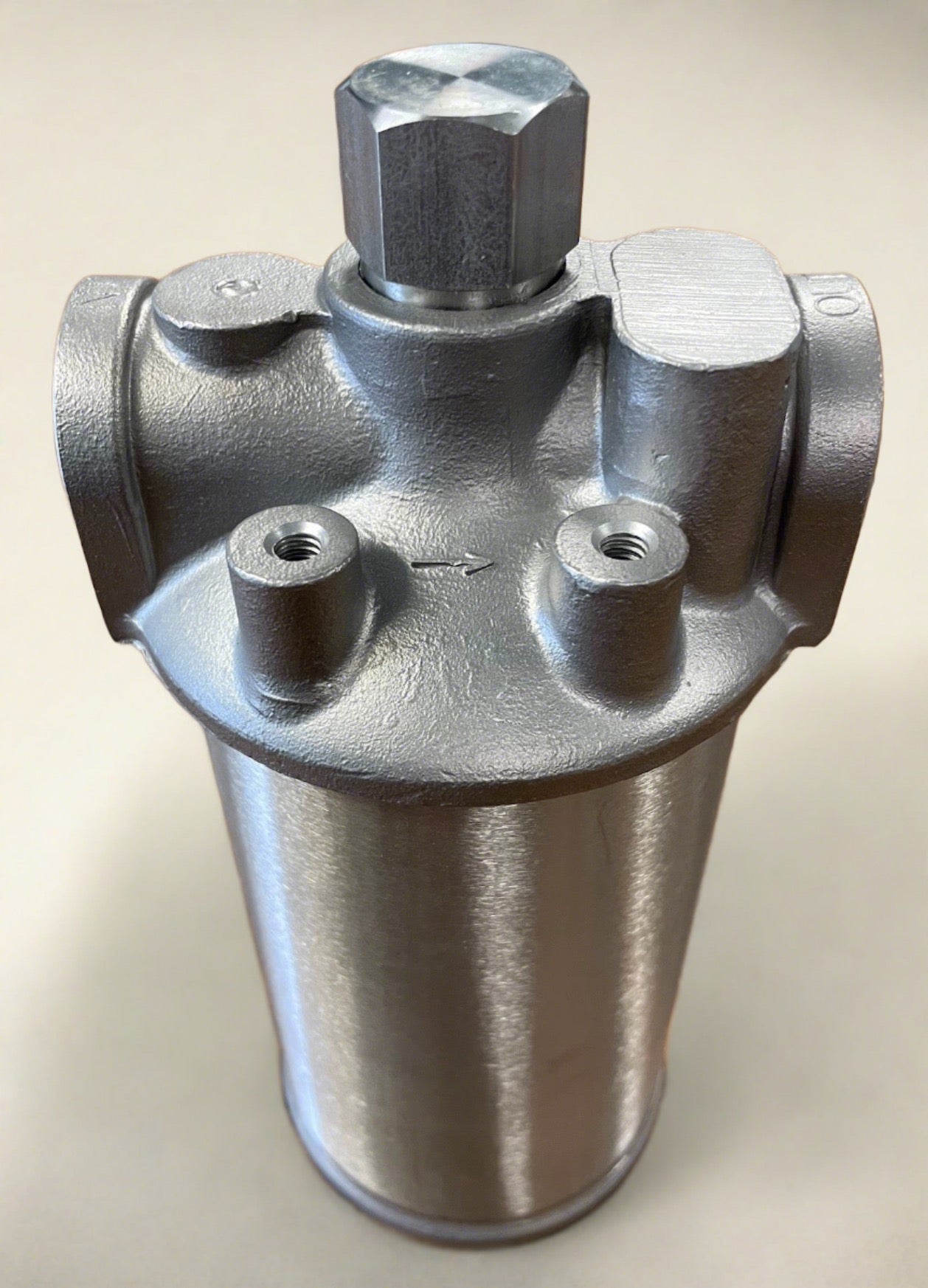

A solvent filter is essentially a device or system designed to remove impurities from solvents. Think of it as a guardian that ensures your solvents are free from particles, debris, and unwanted contaminants. It’s not just about cleanliness; it’s about maintaining the integrity of your processes and products.

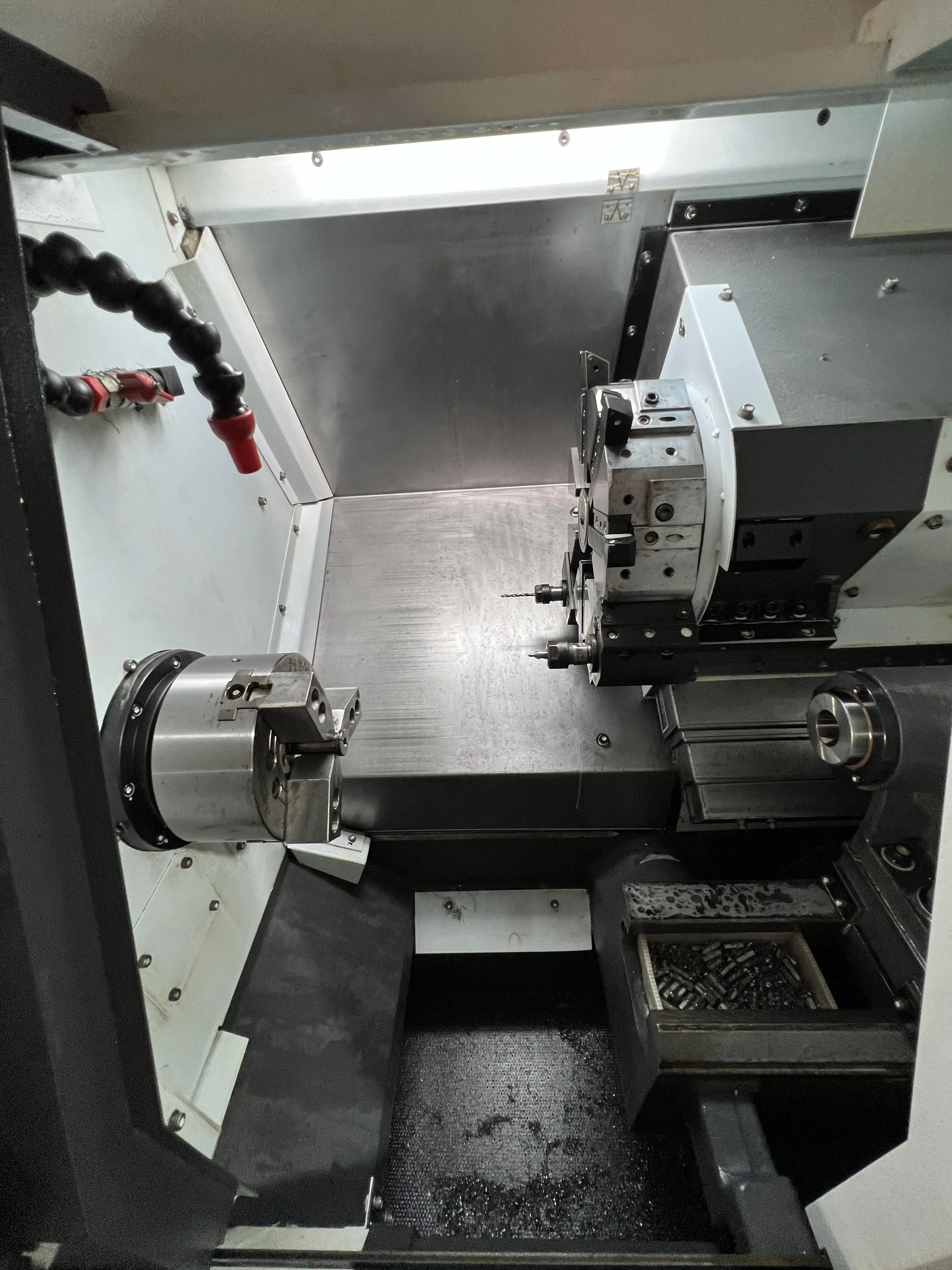

These filters come in various shapes and sizes, depending on the application. From simple syringe filters to complex membrane systems, each type serves a specific purpose. Whether you’re working in a lab or running a large-scale industrial operation, having the right solvent filter can make all the difference.

Why Are Solvent Filters Important?

Here’s the deal: impurities in solvents can mess up your experiments, ruin your products, and even pose safety risks. That’s where solvent filters step in. They act as a barrier, trapping unwanted particles and letting only the pure solvent pass through.

- Who Is Colin Fergusons Wife Discovering The Life And Love Story Behind The Iconic Actor

- Emily Austin Partner The Ultimate Guide To Her Life Career And Achievements

For example, in pharmaceuticals, even the tiniest impurity can affect drug efficacy or safety. In chemical processing, contaminants can clog equipment or cause reactions that lead to product defects. By using solvent filters, you’re ensuring that your solvents are as clean as they can be, which is vital for maintaining quality and safety standards.

Key Benefits of Using Solvent Filters

- Improved product quality

- Enhanced process efficiency

- Reduced risk of contamination

- Longer equipment lifespan

- Compliance with industry regulations

Types of Solvent Filters

Not all solvent filters are created equal. Depending on your needs, you might choose one type over another. Let’s break them down:

Syringe Filters

Syringe filters are compact and easy to use, making them perfect for small-scale applications. They’re often used in labs for filtering small volumes of solvents before analysis or experimentation. Think of them as the Swiss Army knife of solvent filtration—versatile and handy.

Membrane Filters

Membrane filters are the heavy hitters of the solvent filtration world. They’re designed for large-scale operations and can handle high volumes of solvents. These filters come in different materials, such as PTFE, nylon, and polypropylene, each with its own set of advantages.

Cartridge Filters

Cartridge filters are ideal for industrial applications where you need to filter large quantities of solvents. They’re durable, efficient, and can be customized to fit specific requirements. If you’re running a factory or plant, these are the filters you’ll want to consider.

How Do Solvent Filters Work?

The science behind solvent filtration is pretty fascinating. In simple terms, solvent filters work by allowing the solvent to pass through while trapping particles and impurities. This is achieved through a combination of physical barriers and chemical interactions.

For instance, membrane filters have tiny pores that only let the solvent molecules through while blocking larger particles. Some filters also use adsorption, where contaminants stick to the filter material, ensuring that only the pure solvent emerges on the other side.

Choosing the Right Solvent Filter

Selecting the right solvent filter can feel overwhelming, especially with so many options available. But don’t worry, we’ve got a few tips to help you make the right choice:

- Consider the type of solvent you’re working with

- Determine the size of particles you need to remove

- Think about the volume of solvent you’ll be filtering

- Evaluate the compatibility of the filter material with your solvent

- Check the filter’s flow rate and pressure requirements

By answering these questions, you’ll be able to narrow down your options and find a solvent filter that meets your specific needs.

Applications of Solvent Filters

Solvent filters are used in a wide range of industries, each with its own unique applications. Let’s explore some of the most common ones:

Pharmaceutical Industry

In the world of pharmaceuticals, solvent filters are a must-have. They ensure that drug formulations are free from contaminants, which is critical for patient safety. Whether it’s during the manufacturing process or quality control testing, solvent filters play a vital role in maintaining product purity.

Chemical Processing

Chemical processing plants rely heavily on solvent filters to keep their operations running smoothly. By removing impurities from solvents, these filters prevent equipment damage, reduce downtime, and improve overall efficiency.

Environmental Testing

When it comes to environmental testing, accuracy is key. Solvent filters help ensure that samples are free from contaminants, allowing for more reliable and precise results. This is especially important when monitoring water quality or air pollution levels.

Common Challenges in Solvent Filtration

While solvent filters are incredibly useful, they do come with their own set of challenges. Some of the most common issues include clogging, low flow rates, and compatibility problems. Let’s take a closer look:

- Clogging: This happens when the filter becomes blocked with particles, reducing its effectiveness.

- Low Flow Rates: Some filters may not allow solvents to pass through quickly enough, slowing down your processes.

- Compatibility Issues: Not all filter materials are compatible with every solvent, which can lead to chemical reactions or filter degradation.

To overcome these challenges, it’s important to choose the right filter for your application and maintain it properly.

Best Practices for Maintaining Solvent Filters

Just like any other piece of equipment, solvent filters require regular maintenance to function properly. Here are a few best practices to keep in mind:

- Follow the manufacturer’s guidelines for cleaning and replacement

- Inspect filters regularly for signs of wear or damage

- Store filters in a clean, dry place to prevent contamination

- Train staff on proper filter handling and maintenance procedures

By taking good care of your solvent filters, you’ll ensure that they continue to perform at their best for years to come.

Future Trends in Solvent Filtration

The field of solvent filtration is constantly evolving, with new technologies and innovations emerging all the time. Some of the latest trends include:

- Smart filters that provide real-time data on performance and condition

- Environmentally friendly materials that reduce waste and carbon footprint

- Advanced membrane technologies that improve efficiency and capacity

As these trends continue to develop, we can expect solvent filtration to become even more precise, efficient, and sustainable.

Conclusion

So there you have it—everything you need to know about solvent filters. From their importance in maintaining product quality to the various types and applications, these filters are truly indispensable in today’s world. Whether you’re a scientist, engineer, or just someone curious about the science behind purification, understanding solvent filters can open up a whole new world of possibilities.

Now, here’s the deal: if you’ve found this article helpful, we’d love to hear from you. Drop a comment below or share this post with your friends and colleagues. And if you’re looking for more insightful content, be sure to check out our other articles. Until next time, stay curious and keep learning!

Table of Contents

- What Exactly is a Solvent Filter?

- Why Are Solvent Filters Important?

- Key Benefits of Using Solvent Filters

- Types of Solvent Filters

- How Do Solvent Filters Work?

- Choosing the Right Solvent Filter

- Applications of Solvent Filters

- Common Challenges in Solvent Filtration

- Best Practices for Maintaining Solvent Filters

- Future Trends in Solvent Filtration

Detail Author:

- Name : Dr. Keenan Reinger

- Username : rvolkman

- Email : camille.gutmann@bradtke.com

- Birthdate : 1975-10-10

- Address : 560 Cassin Fall East Caterina, OK 25040-0619

- Phone : +1 (234) 987-9819

- Company : Walsh-Greenfelder

- Job : Administrative Law Judge

- Bio : Quidem sint quidem ex est quas. Sint provident et eligendi nisi non et dolorem. Est modi deserunt nulla totam. Expedita velit ab dolores voluptatem aut et neque.

Socials

instagram:

- url : https://instagram.com/camren_lynch

- username : camren_lynch

- bio : Consequatur qui occaecati rerum nisi. Reprehenderit ut eaque itaque.

- followers : 2146

- following : 728

linkedin:

- url : https://linkedin.com/in/lynch1973

- username : lynch1973

- bio : Sit totam rerum aut laborum aliquid quo.

- followers : 5234

- following : 1814